What are the methods of industrial pipe descaling

The inner surface of industrial pipelines is always in contact with different process media, which is easy to bond, sludge, deposit various materials, and even cause pipeline blockage. The most common scaling substances are calcium carbonate and calcium sulphate. If the formation of calcium carbonate scale and calcium sulfate scale in industrial production equipment, pipelines, not only will affect the heat transfer effect, waste of energy; and even cause corrosion under the scale, thus affecting normal use。

At present, China's commonly used descaling methods are mechanical cleaning, chemical cleaning and high-pressure water flushing. But these three have their own advantages and disadvantages, the following first look at the advantages and disadvantages of the three descaling methods。

1、chemical cleaning

Advantage: very efficient, especially for cleaning of duct systems。

Disadvantages: strong expertise, if not careful, not only can not achieve the desired results, but also may damage the pipeline or even cause accidents。

2、Mechanical cleaning

Advantage: removes all dirt, especially chemical non-soluble build-ups such as sand, cokes and certain silicates, etc., and is not corrosive to the metallic materials of the pipeline。

Disadvantage: Its efficiency is much lower than the chemical cleaning method。

3、High-pressure water rinsing

High-pressure water jet cleaning is a method of descaling with the impact force of a high-pressure water stream。

Advantages: high efficiency, no environmental pollution, can be used for the inner wall of the pipeline, the outer space of the tube bundle, etc. to clean the accumulation of scale。

Cons: High-pressure water jetting equipment is a high-risk operating device. High-pressure water jets, like high-speed bullets, can penetrate hard scales and blockages, and can also penetrate and cut off the human body and equipment, operators should guard against water bullets like bullets, to avoid high-pressure water jets injuries and damage to equipment。

Having said that, are you still not sure which method to choose for descaling? Let's take a look at the more advanced electronic descaling technology first。

Electronic descaling technology is in fact divided into many kinds, we first understand the alternating electromagnetic field descaling technology。

Alternating electromagnetic field descaling technology, as the name suggests, is a kind of electronic descaling technology with alternating electromagnetic field as the technical core. The frequency of the alternating electromagnetic field can be transmitted throughout the system, changing the movement of ions in the water. For example, the signal promotes the combination of carbonate and calcium and magnesium ions, which are of course extremely small and not visible to the naked eye. With the help of carbon dioxide, the old scale in the system will gradually dissolve away and all the new and old scale will no longer appear on the pipe wall. Because the dissolved scale is so tiny, it can be discharged with the water flow at any time and anywhere. It also plays the role of descaling and anti-scaling。

Among the existing electronic descaling technologies, the alternating electromagnetic field descaling technology has the following advantages:

1、Long signal transmission distance

2、No need to cut the tube

3、Easy to install and use

4、non-polluting

5、non-stop production

6、Energy saving and consumption reduction

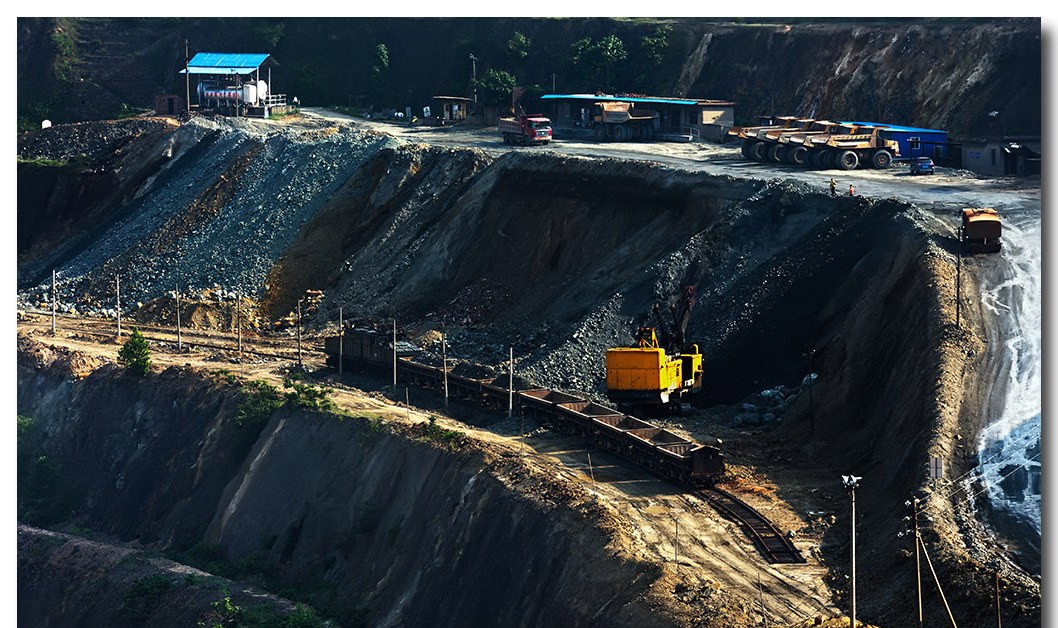

Alternating electromagnetic field descaling technology in industrial pipeline descaling has very significant results, and the scope of application is also very broad, cement plants, thermal power plants, iron and steel mills, textile mills, paper mills, etc. have successful cases。

newest products

Ranking of similar articles

- Closed cooling tower scale formation causes and the harm of scale

- Circulating water descaling and anti-scaling methods

- Comparison of circulating water electronic descaling and traditional chemical

- What are the methods of industrial pipe descaling

- Several common problems of industrial circulating water

Latest news articles

Your browsing history