Several common problems of industrial circulating water

The circulating water operation process often produces problems in the process conditions of industrial production, industrial circulating water quality often occurs in a series of changes, causing harm to production, such as corrosion, scaling, bacteria and algae, slime, etc。

These problems, if not effectively addressed, prevent safe production and cause huge industrial losses。

1、Scale: As the circulating cold cut water evaporates continuously in the process of cold cutting, the salt concentration in the water increases continuously, exceeding the solubility of certain salts and precipitating and adhering to the wall of the system pipe to form scale。

2、Scale: dirt is mainly composed of organic matter in the water, microbial colonies and secretions, sediment, dust, etc. The texture of the scale is fluffy, which not only reduces heat transfer efficiency but also causes corrosion under the scale。

3、Corrosion: circulating cooling water corrosion of heat exchange equipment, mainly electrochemical corrosion, resulting from equipment manufacturing defects, sufficient oxygen in the water, corrosive ions in the water (Cl-, Fe3+, Cu2+) as well as micro-organisms secreted by the mucus generated by the fouling and other factors, corrosion of the consequences of a very serious, uncontrolled very short period can make the equipment scrapped。

Industrial circulating water descaling and anti-scaling technology

Scale control methods

Traditional methods and effects

Requires regular chemical dosing

Scale inhibitors are added to the circulating water to destroy the CaCO3 crystallisation growth process to control scale formation. But long-term pollution of water quality in the environment, and damage to equipment。

Do a good job of circulating cooling water quality treatment

Cooling water in the cycle of use process, such as water quality treatment, will inevitably produce scale or corrosion of equipment, generating corrosion products。

At the same time, there is bound to be an abundance of bacterial growth, which leads to the formation of fouling。

For circulating water systems with chemical leaks a general bypass leakage of 7% or more is appropriate. And regular, regular people backwash, and do a good job of maintenance of the bypass filter。

Long-term physical and human investment is not stable enough to control. Inability to ensure the efficient and safe operation of the system。

So Is not a lot of trouble, there is a new technology within the market for water processors, that is not only convenient, a wide range of uses and environmental protection。

Como Electronic Water Processor

1、No need to add chemicals to remove scale and scale prevention, Como electronic water processor uses the use of alternating electric field of physical way to deal with cooling circulating water, scale prevention and scale inhibition, bactericidal algae and other issues。

2、Increase the concentration factor, reduce the amount of sewage and water replenishment, high efficiency and save water resources, 24-hour automatic processing, reduce the workload of personnel, without special maintenance。

The working principle of Como's electronic water processor

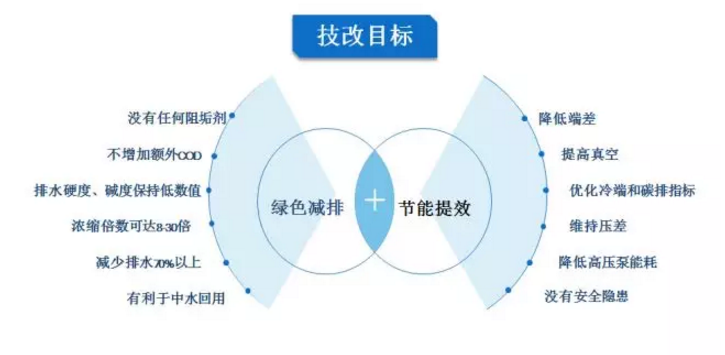

Como electronic water processor is chemical additive-free, to protect the environment, and save money, water reuse is simple, reverse osmosis system water yield and other optimised。

Water savings and emission reductions in a green way can significantly reduce the difficulty of achieving zero emissions in power plants。

newest products

Ranking of similar articles

- Closed cooling tower scale formation causes and the harm of scale

- Circulating water descaling and anti-scaling methods

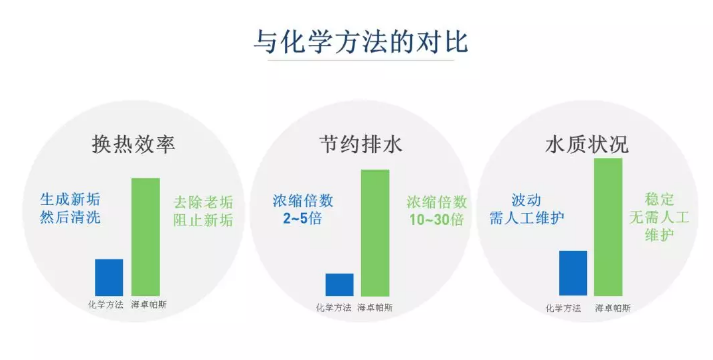

- Comparison of circulating water electronic descaling and traditional chemical

- What are the methods of industrial pipe descaling

- Several common problems of industrial circulating water

Latest news articles

Your browsing history