Research on the application of Como electronic water processor in reverse osmosi

Wenxue Zhang

Guodian Xingyang Coal and Power Integration Company Limited No. 1 Guodian Avenue, Xingyang City, Henan Province, China 450119

abstract:This article introduces a new physical water treatment technology, the Como water processor, explaining its working principle and its three functions: scale inhibition, sterilization, and flocculation.Through the analysis of scale inhibition application tests conducted on our company's reverse osmosis system, it is demonstrated that the Como water treatment system can replace reverse osmosis scale inhibitors under certain conditions, ensuring the safe and normal operation of reverse osmosis。

Keywords: Como, physical technology, scale inhibition, reverse osmosis, normal operation

I. The working principle of Como water processor

Como water processor in the alternating electric field under the action of electromagnetic waves with a frequency of 120~200KHz, electromagnetic waves directly on the water: not subject to the limitations of the pipeline distance and type of pipe, not subject to the speed and temperature of the water flow. The special electromagnetic waves generated by the equipment to water as a carrier throughout the water system, and change the physical properties of calcium, magnesium and other ions, so that calcium carbonate becomes suspended in the water of the ionic group (not in the inner wall of the equipment to form a hard scale), through the filtration device or precipitation sewage, etc. will be removed, to achieve the purpose of the anti-scaling[1~4]。

When the water flows through the strong electromagnetic wavering, the electromagnetic wave can kill most of the algae spores and bacteria, so that the algae can no longer reproduce, solving the problem of bacterial growth and slime adhesion。

Alternating electric field signals generated by Como water processors

II. the function of the Como water processor

Como water processor has scale treatment, alga sterilization, and physical flocculation ability. The specific analysis is as follows:

2.1、Function One ——detergent and antifouling

The Como water processor signal can promote the precipitation of calcium carbonate crystallisation in the water column, the formation of calcium carbonate under these conditions is fluffy (aragonite calcium carbonate), can be discharged with the water flow, will not be scaled on the pipe wall and other surfaces; if the system already has the presence of the old scale, in the Comowater processor signal, the old scale will also be gradually removed, and the pipe wall, the tank and other containers will not have a new surface of the water scale. Generation. In addition, Como's signal can effectively inhibit other ionic scales, such as calcium sulphate, calcium phosphate, etc.[5~7]。

Naturally crystallised calcium carbonate crystals Formation of calcium carbonate crystals promoted by Como

Calcite structure aragonite structure

2.2、Function 2 ——sterilisation and algaecide

Como water processor through the alternating electric field signal effect, making bacteria and algae spores on the surface of the formation of pure water environment, the use of the role of diffusion of the concentration difference, bacteria and algae spores on the surface of the water molecules continue to infiltrate its body, ultimately resulting in the rupture of the spore cell wall to achieve the purpose of killing bacteria and algae spores.[8~11]。

cytoplasm“demolish” the whole process

2.3、Function 3——willow flower

To make the suspended particles in the water or liquid phase gather larger or form flocs to accelerate the process of solid-liquid separation, a phenomenon we call flocculation。

Como water processors through the alternating electric field effect on the water-charged colloids and suspended matter interference, prompting them to hold the group to become larger, through precipitation or filtration and other ways of separating it from the water body, thus achieving the purpose of flocculation turbidity reduction。

Schematic diagram of the flocculation process

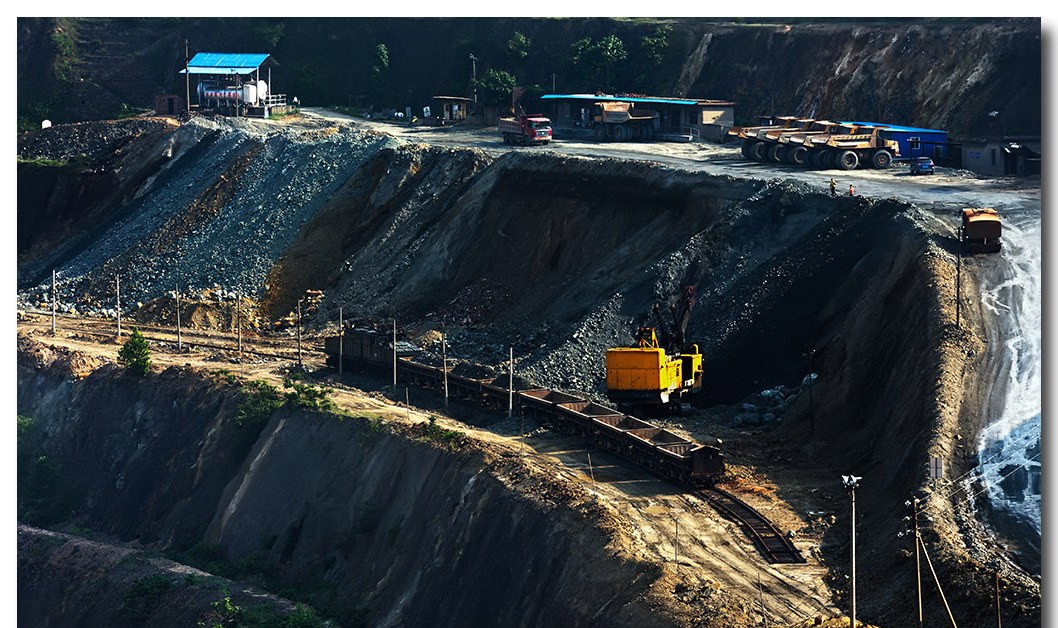

III. Como water processor in my plant RO system application analysis

Guodian Xingyang Power Plant has two reverse osmosis (RO) sets with an inlet flow rate of 80 tonnes per hour and a recovery design of 70%. On 6th September 2016 Como water processor was installed in front of RO membrane set No.1 and membrane set No.2 was not installed. Among them; the scale inhibitor of the No.1 RO membrane was reduced by 50% on 26th September 2016, and during the operation period, the desalination rate, differential pressure, and water production of the No.1 membrane were not significantly different from the previous operation; No.1 reverse osmosis stopped using the scale inhibitor on 15th October 2016, and operated until 6th November. The main operating parameters of the No. 1 membrane did not change during the operation period. It indicates that the No. 1 membrane does not have scale attachment under the condition of not adding a scale inhibitor。

According to all the operating data and water quality data, we determine the Como water processor in the reverse osmosis membrane before the descaling and scale inhibition effect, fully able to meet the reverse osmosis safe and normal operation. The following are the statistics and analysis of the operation data and water quality monitoring from 6 September to 6 November。

3.1、Reverse osmosis operation data analysis chart

2016.9.6-11.06 Desalination rate of Reverse Osmosis membranes 1,2

2016.9.6-11.06 Differential pressure between segments of reverse osmosis membranes No. 1,2

2016.9.6-11.06 Flow rate of water produced by reverse osmosis membranes No. 1,2

3.2、Reverse osmosis water quality testing data analysis charts and graphs

2016.9.26-11.06 Reverse osmosis feed water No. 1,2, membrane concentrate water quality test

From the data, it can be seen that the 1# membrane concentrated water data fluctuated a lot during the pre-descaling process, but during the scale inhibition process, especially after there was no interference from chemicals, the concentrated water data was smoother, and all of them were always significantly lower than that of the 2# membrane. At the same time, no drop in module operating parameters occurred. This is in line with the working characteristics of the Como water processor: it promotes the formation of loose aragonite-like calcium carbonate, which can flow out with the water. On the one hand, there is no scale adhering to the membrane surface, and on the other hand, the reduction in hardness and alkalinity helps to reuse the concentrated water。

Based on the above functions and principles, we can utilise the physical flocculation ability of Como to help pre-treatment equipment improve interception capacity, especially for water reuse projects. Using the scale treatment ability to be installed before the reverse osmosis membrane maximises the possibility of prolonging the membrane clogging condition, which can eliminate the need for scale inhibitors, reduce the hardness, alkalinity and other indicators of concentrated water, and enhance the possibility of reuse。

Attachment 1: Descaling process data

Reverse osmosis (RO) concentrate water quality tests of the descaling process clearly show the dissolution of the old scale (which lasted about two weeks).:

SH-COMO Water Quality Test Results(Water samples on 2016-9-13):

| serial number | sensing | unit (of measure) | raw water | 1# | 2# | note |

| 1 | PH |

|

8.4 | 8.3 | 8.5 |

|

| 2 | TDS | ppm | 500 | 1200 | 700 | TDS means Total Suspended Solids dissolved in water。 |

| 3 | conductivity | μs/cm | 600 | 1200 | 1320 | Conductivity measures the ability of ions in water to conduct electricity。 |

| 4 | total hardness | mg/L | 255 | 700 | 440 | Total number of calcium and magnesium ions contained in water |

| 5 | alkalinity | mg/L | 285 | 760 | 800 | The total amount of substances contained in water that interact quantitatively with strong acids。 |

The above tests are presented as follows:

1、There is a significant difference in the hardness index of the two concentrated waters, with little difference in alkalinity。

2、 The conductivity of 1# is slightly lower than 2#.。

3、 We also examined the concentration of SO

4,Almost non-existent, so the indicator is no longer monitored。

The analysis is as follows:

1、The actual recovery rate in the field is about 70%, so the concentrated water is concentrated more than 3 times. The 1# membrane desalination rate is slightly higher than the 2# membrane, which means that the amount of ions in the concentrated water of the 1# membrane is slightly higher than that of the 2# membrane. 1# membrane concentrated water conductivity is lower than 2#, which is supposed to be the result of some of the ions being combined by the Como signals in the concentrated water to reduce the electrical properties。

2、Adding scale inhibitor on site has little effect on alkalinity and more effect on hardness, so the alkalinity of 2# membrane is less than 3 times, which indicates that there is calcium carbonate generated on the membrane surface. It also proves that there is a calcium carbonate scale present on the surface of 1# membrane. Hardness is lower because of the formation of crystals with scale inhibitor。

3、The reason that the alkalinity of 1# membrane is slightly lower than that of 2# membrane and the hardness is higher instead is that the calcium carbonate on the surface of 1# membrane is continuously removed by the signals of Como equipment. And in the middle there is the process of dissolving in water in the form of calcium bicarbonate, in addition, the signal of Como will make the scale inhibitor can't combine with calcium and magnesium ions normally, and we are disturbed by the scale inhibitor is not easy to promote the generation of more calcium carbonate, so the hardness will increase. At the same time, the existing calcium and magnesium ions and bicarbonate in the raw water will be combined under the effect of the Como signal, so the hardness of the 1# membrane is much higher than that of the 2# membrane, and the alkalinity decreases slightly。

Reach a verdict:

1、Some of the scale on the reverse osmosis membrane in system #1 has started to dissolve。

2、Scale inhibitors are a hindrance to the rate of descaling。

3、1# Hardness and alkalinity will show a decrease during the reduction process。

4、At the end of descaling, the concentration data of membrane #1 will be lower than that of membrane #2, and the operational status of the membrane will be improved。

5、After descaling is complete, the concentration data for the anti-scaling process 1# membrane will change。

Attachment 2: Photo of Membrane 1 installation on site

The domestic part of the project case

| Guangxi Laibin Smelter | Phoenix Paper Mill |

| Daqing oilfield | Taiyuan Iron and Steel |

| Beijing Jingmen Mansion | Friendship Hotel |

| Samsung Chemical | Jinan Iron and Steel Works |

| Marriott Hotel | Shanghai Renji Hospital |

| Shanghai Ruijia Hotel | Shanghai Tongji Hospital |

| Shanghai Kinsey Pharmaceuticals & Chemicals | Shanghai IFC Centre |

| Shanghai Automotive Powder | Shanghai Automotive Works (SAAW) |

| Atlas China Ltd. | Fusheng Air Compressor Co. |

| Ingersoll Rand Air Compressor | Yanzhou Coal Mine |

| Pingdingshan coal mine | Kunshan Wangquan Electronics |

| BYD factory | Ruiping Power Plant |

| Foxconn China | Ningbo Quan Sheng Shell |

| Langfang Development Zone Heat Centre | Langfang Unicom Cloud Data Centre |

| Ji Dong Cement (Tianjin FAW) | Tianrui Cement |

| Yili Group | Qingdao Haier |

| Hangzhou Bay Plating Park | Formosa Plastics Ningbo |

| Xinao Gas Group | Luoyang Heat Centre |

……

Offshore power plant projects are mainly concentrated in the following countries and regions:

| Russian power plants | Japanese power plants |

| Hong Kong Power Station | Taiwan power plant |

References

[1] Xiumei Zhuang. Power plant water treatment technology[M]. Beijing: China Electric Power Press, 2009.

[2] Lisha Song. Water technology for thermal power plants[M]. Beijing: China Electric Power Press, 2007.

[3] Xiaoyun Li, Zhanghua, Xibing. Thermal power plant water use and water conservation technology[M]. Beijing: China Water Conservancy and Hydropower Press, 2007.

[4] Boqing Zhou, Zhihe Chen. Thermal power plant water treatment[M]. Beijing: China Electric Power Press, 2009

[5] Wang Yang, Yangbo Huang, Yu ping.etc. Research on high-frequency electromagnetic scale inhibition and its mechanism[J]. Industrial water treatment, 2015,35(2): 23~26.

[6] Baker J S, Judd S J. Magnetic Amelioration of Scale Formation [J]. Water Research, 1996, 30(2):247~260.

[7] Amr Abou-Ghazala, Karl H. Schoenbach. Biofouling Prevention with Pulsed Electric Fields [J]. IEEE Transactions on Plasma Science, 2000, 28(1):115-121.

[8] Hao fu, Zhou rong, Zhouquan.etc. Advances in pulsed magnetic field sterilisation technology[J]. Jiangxi Science, 2014,32(1):86~91.

[9] Monfort S, Gayan E, Raso J, et al. Evaluation of pulsed electric fields technology for liquid whole egg pasteurisation [J]. Food Microbiology, 2010,27 (7):845~852.

[10] Liuwei, Ruihong Liang, Chengmei Liu.etc. Mechanism of action of pulsed magnetic field sterilisation and its application[J]. Grain and Food Industry, 2005,12(1):52~54.

[11] Dandan Guo, Kaijun Xiao. Study of milk sterilisation by high-intensity pulsed magnetic fields[J]. Food Research and Development, 2010,31(7):42~45.

newest products

Ranking of similar articles

- Research on the application of Como electronic water processor in reverse osmosi

- The effect of Como is obvious in central air conditioning condenser

- Como makes the equipment low energy consumption and good effect

- Como makes the boiler with high coal saving rate and less residue

- Como works very well and saves costs

- Como has a good descaling effect on boilers

Latest news articles

Your browsing history