Descaling and anti-scaling for power plants

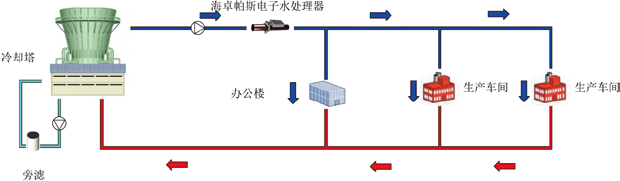

Power plant scale problems mainly occur in the cooling system. The process of descaling and anti-scaling, algaecide and sterilisation in this system mainly adopts the traditional chemical method. This method is costly, usually ineffective and difficult to meet the current requirements of energy saving and emission reduction. This problem has caused problems for many power plant enterprises。Como uses national patented technology (Note: Chinese invention, patent number:ZL2020 1 0038217.7 ) ,Using purely physical methods to remove scale, prevent scaling, eliminate algae, and sterilize, without the need to add any chemical agents, can prevent scaling in the system at high concentration ratios, significantly reduce drainage, and make the water quality more suitable for reuse。“Make zero emissions no longer just a goal!”。

Disadvantages of traditional chemical water treatment processes:

1、Scale is still present in the inner walls of heat exchangers, such as condensers, and in the packing of cooling towers。

2、It is even more difficult to control water quality such as high salt and high hardness。

3、Chemical side effects on system equipment are unavoidable。

4、Recycling of drainage water is difficult due to the addition of chemicals。

5、Concentration is generally controlled at 2-6 times, wasting too much water。

Special features of Como for cooling circuits:

1、Scale removal and prevention, physical flocculation and algaecide and sterilisation can be completed in one set of equipment。

2、No need to add scale inhibitors and other chemicals。

3、Enables operation at high concentration levels (over 20 times) and reduces water discharge by over 70 per cent。

4、Zero-additive, easy to discharge, easy to recycle。

System Schematic

info@como-aqua.com

Company address:Building 9, No. 285 Rongxing Road, Songjiang District, Shanghai