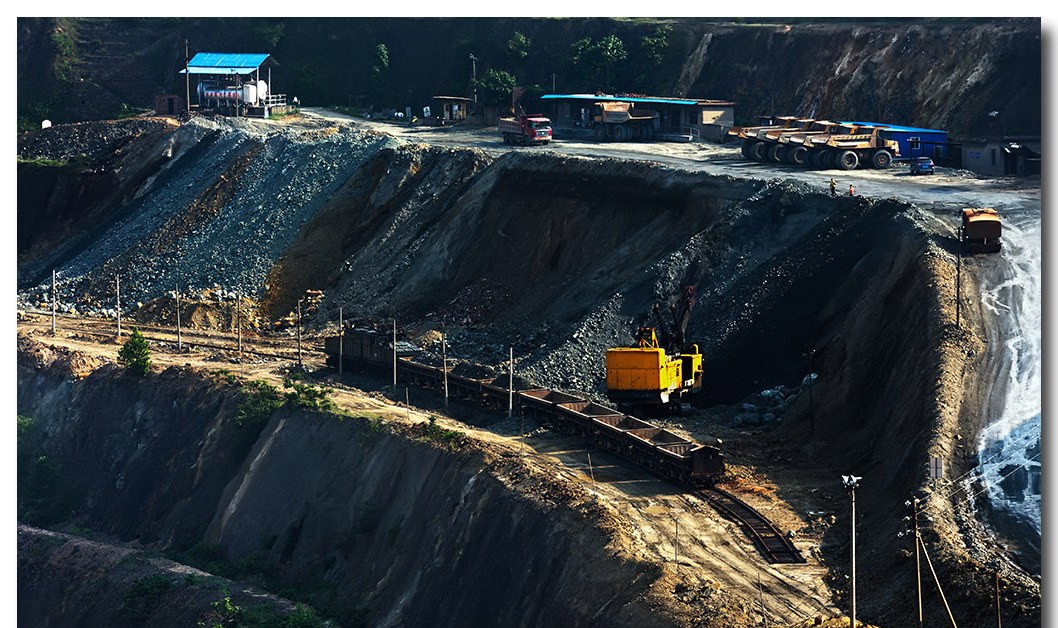

Cement plant descaling and anti-scaling

The problem of water scaling in cement plants mainly occurs in cooling systems and heat exchange equipment. These parts are often scaled due to water quality, resulting in lower heat exchange efficiency, increased energy consumption and shorter life of the parts. If the scale cannot be removed in time, there is a risk of equipment repair, downtime or scrap replacement. Long-term traditional cleaning methods such as mechanical methods (scraping, brushing), high-pressure water, chemical cleaning (pickling), etc. in cleaning equipment will have many problems. These problems have caused issues for many cement plant enterprises。 Como uses nationally patented technology (Note: Invented in China, Patent No.:ZL2020 1 0038217.7 ), It can help cement factories to remove and prevent scale by purely physical means, eliminate algae and sterilise without adding any chemicals, and make the system non-scaling at high concentration multiples, greatly reducing drainage and making the water quality more suitable for reuse.。“Making zero emissions more than just a goal!”

Problems caused by traditional cleaning methods:

1、The use of mechanical methods (scraping, brushing) and high-pressure water does not completely remove deposits such as limescale。

2、The use of chemicals, which produce acid that can cause corrosion of the equipment to form vulnerabilities。

3、After pickling, the residual acid produces secondary corrosion or sub-scale corrosion on the equipment material, eventually leading to the replacement of the equipment。

4、The waste liquid from pharmaceutical cleaning is toxic and cannot be discharged directly, and if wastewater treatment is carried out, it will require a large amount of capital。

Adoption of Como electronic water processor:

1、Compared with traditional chemical water treatment methods, Como Electric can meet the requirements of customers for scale-free system operation, water and energy saving without adding chemicals, and the water is cleaner and of better quality。

2、Como adopts a special alternating electric field method to make the ions in the water continuously reciprocate, and when the solubility decreases (temperature rises, pressure decreases, and concentration increases), it promotes their combination to form a loose aragonite calcium carbonate suspended in the water, which flows out with the water and precipitates at the bottom of the pool through sewage discharge, or the by-pass filtration system filtrates it out to ensure that there is no scale adhesion on the inner wall of the system and pipeline。

3、While preventing the growth of limescale, the Como water processor signal also removes existing old scales.

4、Como water treatment equipment can stop the advancement of the corrosion process by inducing a coaxial electromagnetic field through the solute, controlling the movement of negatively charged electrons to the outside of the vessel and attracting positively charged ions away from the surface to a passivated state. Reduces galvanic corrosion rates by up to 70 %。

info@como-aqua.com

Company address:Building 9, No. 285 Rongxing Road, Songjiang District, Shanghai