Report on the Technical Modification of the Cooling Water System for Production Lines 7 and 8 of Safety Glass

Safety Glass is one of the leading enterprises in the Shahe glass industry, with 8 float glass production lines, including heat exchange devices such as water packages and air compressor units. It uses soft water and chemical agents for daily maintenance to ensure continuous and stable production。

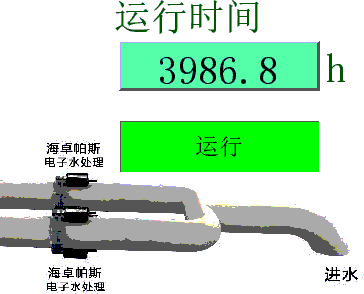

To protect the production lines in a more environmentally friendly and safer manner, on November 18, 2017, production lines 7 and 8 attempted to replace chemical agents with physical technology: three sets of Como water processors were installed outside the production cooling water and air compressor cooling water pipelines, as shown in the figure below:

The installation status of the Como water treatment system for the 78-line production cooling system on-site.

On-site and remote monitoring show that it has been running continuously for over 5 months.

During the more than five months of uninterrupted operation of the anti-scaling agent, the site experienced:

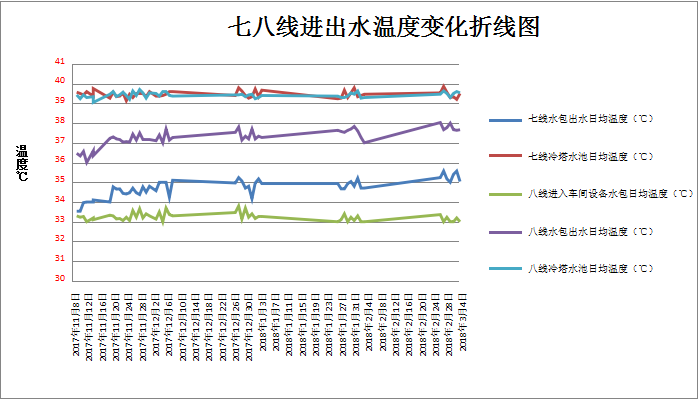

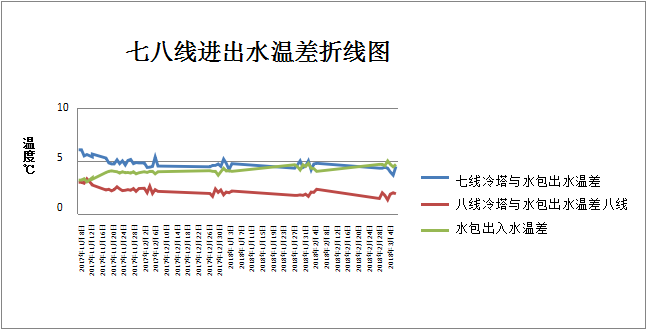

1. In the initial two weeks, the temperature difference on lines 7 and 8 rose from 3.2°C to 4°C and stabilized around 4°C. This was during the descaling process, which improved the water package's heat exchange efficiency. When the water package was replaced in March, the absence of scale inside the water package supported this argument。

2. The filtration device configured by the system has undergone more frequent cleaning. This is due to the descaling, anti-scaling, and physical flocculation functions of the Como water processor. It also demonstrates that the system operates efficiently with the help of the physical signals from the water processor without the use of anti-scaling agents or other chemicals。

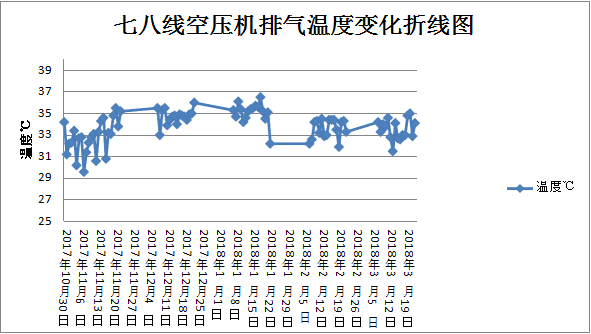

3. From the on-site recorded water quality data (hardness consistently maintained within 50ppm), the temperature difference between the inlet and outlet water of the production line is maintained at around 4℃, and the exhaust temperature of the air compressor is maintained at 31-37℃, all indicating that the system is in good operating condition。

4、When the Como water purifier was used for 4 months, the on-site water bag was replaced. After cutting it open, the previous water quality changes were confirmed: from descaling to anti-scaling, there was no scale inside the entire water bag(see attachment)。

Summary: A comprehensive comparison of the system's performance over the years shows that, although no scale inhibitors were added, the system did not experience any negative issues and even performed better than before(the water tank was completely free of scale, and heat exchange efficiency was high)。 The use of the Como water treatment system has helped companies break free from the constraints of chemical agents, providing new ways for more convenient management。

Currently, this technological transformation helps The annual savings on chemical costs for the company amount to 1.2 million yuan。 The zero addition of chemicals also significantly enhances the company's image, and there are additional economic benefits as follows:

|

1 |

Cost-effectiveness of air compressor cooler cleaning |

Hundreds of thousands of yuan per year |

|

2 |

Cost-benefit analysis of replacing the air compressor cooler |

Hundreds of thousands of yuan per year |

|

3 |

Cost-effectiveness of cleaning refrigeration units |

Hundreds of thousands of yuan per year |

|

4 |

Cost-benefit analysis of replacing the chiller unit's cooler |

Hundreds of thousands of yuan per year |

|

5 |

Avoid production waste caused by replacing water bags due to scale buildup |

Millions of yuan per year |

|

6 |

Extending the lifespan benefits of air compressor systems and refrigeration systems |

Hundreds of thousands of yuan per year |

|

7 |

Save on water bills |

Millions of yuan per year |

|

8 |

Saving on sewage charges |

Millions of yuan per year |

|

9 |

Save the power consumption of the water pump |

Hundreds of thousands of yuan per year |

It is evident that this technological transformation has brought significant economic returns to the company without affecting production, making it worthy of promotion throughout the entire plant。

Based on the production requirements and the current state of the system, we propose the following recommendations:

If the use of softened water is stopped and local industrial water is used instead, relying solely on the Como water treatment system will result in more mineral scale that needs to be removed through the filter device, requiring more frequent cleaning. Considering the importance of continuous production on the glass production line and the relatively low cost of softened water, we recommend that the safe glass cooling water system maintain the maintenance mode that has been in use for over five months: softened water + Como water treatment.

Attached: Photos of the replaced water bag and the data curve chart from the past five months

Due to the high temperature, the water bag was replaced, and the interior was completely free of impurities. This was completely different from previous experiences. The effectiveness of the Como water processor was confirmed and praised by the on-site staff。

Cooling system descaling and anti-scaling

Steam boiler scale control

Scale-prevention of hot water boiler

Waste heat boiler scaling

Waste heat recovery equipment scaling

Thermal center scaling and anti-scaling

Reverse osmosis membrane scale removal and anti-fouling

Descaling and Fang of plate heat exchanger

Descaling and fang of steam generator

Air can remove scale and prevent scale from water heaters

Shell and tube heat exchanger scale removal and prevention

Kitchen equipment scale control

Central air conditioning system scale control

Hotel hotel scale control

Chemical plant scale removal and control

Descaling and anti-scaling in mining and metallurgical plants

Hospital scale removal and prevention

Descaling and deterring of iron and steel works

Mining plant scale removal and control

Air compressor scale control

Power plant scale removal and control

Cleaning and preventing scale in paper mill

Scale removal and anti-scaling in electronics factory

Electroplating plant scale control

Cleaning and preventing scale in printing and dyeing plant

Cleaning and preventing scale in food factories

Domestic hot water system to remove and prevent scale

info@como-aqua.com

Company address:Building 9, No. 285 Rongxing Road, Songjiang District, Shanghai