Como technology is used in power plant reverse osmosis membrane cases.

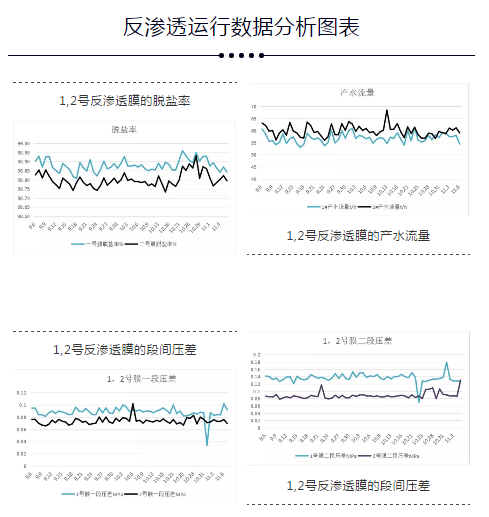

The reverse osmosis system of this power plant uses groundwater as its water source, which contains a lot of minerals. The data also varies with seasonal changes. It requires chemical cleaning more than twice a year。 According to feedback from the operations and maintenance personnel: although chemical anti-scaling has always been used, chemical cleaning is required more than twice a year, and each cleaning does not completely remove the scale. After analyzing the water quality data, it was confirmed that there is CaSO4 on the membrane surface。

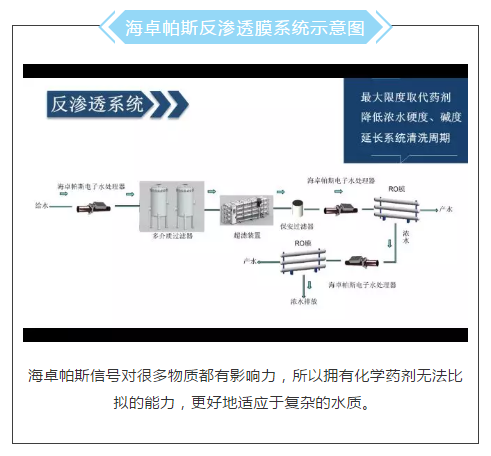

The power plant has two sets of reverse osmosis systems, with an inlet flow rate of 80 tons/hour and a designed recovery rate of 70%. A Como water treatment system is installed before the first RO membrane group, while the second membrane group is not equipped with one。

The Como water treatment equipment was installed after the high-pressure pump before the 1# reverse osmosis membrane, and a two-month continuous test comparison of reduced and stopped dosing was initiated.

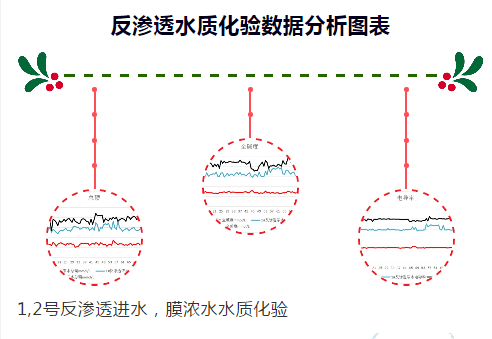

At the same time, conduct parallel comparisons with Module 2. To achieve zero emissions in the future, continuously monitor the quality data of the reverse osmosis concentrate during the testing period。

From the data, it can be seen that during the initial descaling process, the concentration data of Membrane 1 fluctuated significantly. However, during the anti-scaling process, especially without the interference of chemical agents, the concentration data became more stable and consistently lower than that of Membrane 2. At the same time, the module operating parameters did not decline, which aligns with the operational characteristics of the Como water processor。

The company recognized the descaling and anti-scaling effects of the Como water processor before the membrane through a series of data changes.

A status monitoring cabinet has been installed on-site, allowing for remote monitoring of equipment status, reducing personnel workload, and eliminating the need for special maintenance。

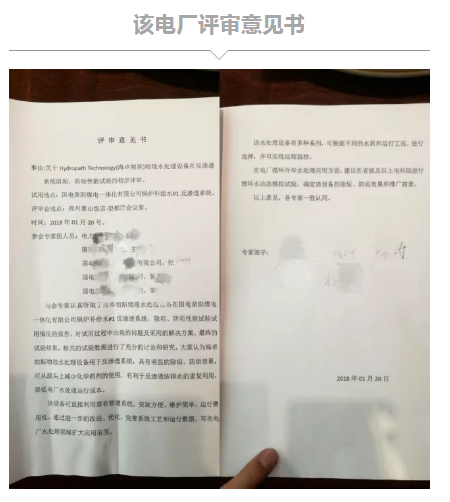

It has been over a year since the installation of the Como water treatment system at the power plant. Several experts from well-known power companies have conducted a preliminary review of the Como system. They believe that the Como water treatment equipment, used in reverse osmosis systems, has a significant descaling and anti-scaling effect. This is beneficial for the reuse of reverse osmosis concentrate and reduces the operational costs of water treatment at the power plant。

Witness:

Party A hosted some visitors and published a paper in an internal technical exchange journal of the power industry. They also continued to report on the feasibility plan for using Como Water Treatment Systems in the cooling circulation water system。

The Como water treatment device penetrates pipes using electromagnetic waves, affecting ions in the water and controlling their movement. This allows for scale prevention and removal without the need for anti-scaling agents, ensuring the safe and normal operation of the reverse osmosis system。

Under the influence of the Como water treatment signal, calcium carbonate can crystallize and precipitate in the water body. In this case, the calcium carbonate formed is soft (aragonite structure calcium carbonate) and can be discharged with the water flow, preventing scaling on surfaces such as pipe walls。

The role of the Como water processor in the membrane system:

1、Utilize the unique physical flocculation function to enhance the interception efficiency of the primary filter。

2、The signal from Como can penetrate the pores of each membrane layer, removing the calcium carbonate scale and inhibiting the formation of the calcium sulfate mineral scale。

3、Partially or completely replace scale inhibitors to reduce long-term operating costs。

4、Reducing the hardness and other indicators of concentrated water is more beneficial for the recycling of concentrated water。

5、Extend the cleaning time and lifespan of the membrane。

6、Reduce the outlet pressure of the high-pressure pump within a reasonable range to save energy consumption。

However, the rate of change in operational data may vary due to differences in water quality and membrane conditions. Generally, after installing and using the Como water processor, the above phenomena will gradually appear within 1-30 days. Especially for reverse osmosis membranes with a higher cleaning frequency。

Cooling system descaling and anti-scaling

Steam boiler scale control

Scale-prevention of hot water boiler

Waste heat boiler scaling

Waste heat recovery equipment scaling

Thermal center scaling and anti-scaling

Reverse osmosis membrane scale removal and anti-fouling

Descaling and Fang of plate heat exchanger

Descaling and fang of steam generator

Air can remove scale and prevent scale from water heaters

Shell and tube heat exchanger scale removal and prevention

Kitchen equipment scale control

Central air conditioning system scale control

Hotel hotel scale control

Chemical plant scale removal and control

Descaling and anti-scaling in mining and metallurgical plants

Hospital scale removal and prevention

Descaling and deterring of iron and steel works

Mining plant scale removal and control

Air compressor scale control

Power plant scale removal and control

Cleaning and preventing scale in paper mill

Scale removal and anti-scaling in electronics factory

Electroplating plant scale control

Cleaning and preventing scale in printing and dyeing plant

Cleaning and preventing scale in food factories

Domestic hot water system to remove and prevent scale

info@como-aqua.com

Company address:Building 9, No. 285 Rongxing Road, Songjiang District, Shanghai