Application Data and Analysis of Alternating Electromagnetic Fields in Power Plant Cooling Water Systems

Xiaoning Yang Shuming Fu

Chemical Engineer at Shanxi Sunshine Power Plant

Abstract: As the national requirement for zero discharge of industrial wastewater is gradually implemented, the cooling water system needs to ensure scale inhibition、 While descaling, try to increase the concentration ratio as much as possible, reduce make-up water and drainage, and ensure that the heat exchange efficiency in production remains stable and it cannot be reduced, which has become a top priority for all enterprises. The application of electromagnetic field water treatment technology can achieve effects such as scale prevention、descaling, sterilization, algae removal, corrosion inhibition, and rust removal, thereby achieving the goals of high efficiency, energy saving, and environmental protection。

Keywords: Alternating electromagnetic field; Crystallization granulation; Cooling water descaling and anti-scaling; Concentration ratio; Zero wastewater discharge; Artificial intelligence surveillance

Shanxi Sunshine Thermal Power Plant has installed four 320MW generator sets, each with an independent cooling circulation system. The dual circulation pumps and condensers are located in the turbine room, and the system is designed for a circulation flow rate of approximately 20,000—35000 m3/h。The circulating water system is an open-loop system, with water sources including reservoir water, municipal reclaimed water, groundwater, and other sources. The circulating water system uses traditional chemical scale inhibitors and agents to ensure the system operates without scaling and with low corrosion. Due to water quality constraints, the concentration ratio of circulating water is mostly maintained at around 4 times。 With the gradual implementation of the national requirement for zero discharge of industrial wastewater, cooling water systems need to increase the concentration ratio as much as possible while ensuring descaling and anti-scaling, reducing makeup water and drainage and ensuring that the production heat exchange efficiency remains stable and does not decrease. This has become an urgent priority for all enterprises。

1、Implementation of the technical modification plan

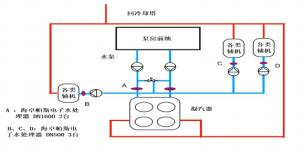

The cooling circulating water of the generator set is the main water system in the plant area. To improve the operational efficiency of the unit and implement energy conservation, emission reduction, and achieve zero emissions, physical technology is used to replace the original chemical method and the cooling water circulation 1 system in the plant area is being transformed and tested with ultra-low emission physical technology。2020 year 8 At the beginning of the month, two sets of electromagnetic water treatment devices were installed on the outlet branch of the circulating water pump, and three sets of electromagnetic water treatment devices were installed on the inlet pipeline of the auxiliary machine's circulating water. The schematic diagram of the installation locations of the electromagnetic field water treatment devices in the technical modification plan is shown below:

Figure 1

Through the artificial intelligence monitoring system, the working status and main technical parameters of the electromagnetic water treatment equipment are monitored in real-time at the power plant's centralized control centre。

The alternating electromagnetic field technology, through the principle of electromagnetic induction, can alter the movement of charged substances in water, thereby achieving descaling and anti-scaling, physical flocculation, algae elimination and sterilization, and corrosion inhibition in cooling circulating water systems。[1]

2、Analysis of the Operational Data of the Generator Set Cooling Circulation Water System

2.1 Water quality data

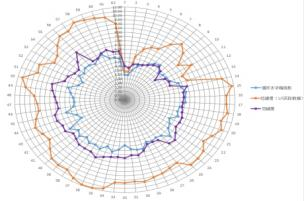

After the installation and commissioning of the electromagnetic field water treatment equipment in the 2020 year 8 month, the effect of the electromagnetic field was confirmed through tracking and analyzing water quality data and unit operation data, and then emission reduction operations were initiated. The concentration ratio increased from approximately 4 times before the technical transformation to around 6 times. During the three-month trial operation, the water quality data remained relatively stable, and the concentration ratio was maintained at 6~7 times。 The trend chart of water quality data changes is as follows:

Figure 2 Water Quality Data Trend Chart

From Figure 2 it can be seen that after the technical transformation, the concentration multiple of the cooling circulating water has significantly increased, and the hardness and alkalinity of the water quality have also correspondingly improved。

2.2 Generator unit operating data

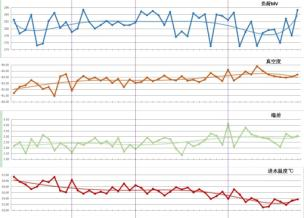

The unit has been running continuously for three months,1# The operating parameters of the generator set are generally stable, with the condenser end difference and vacuum maintained within a stable range. The unit operation data curve is as follows:

Figure 3 Unit operation data curve chart

From the operating parameter curve, it can be seen that the unit's power generation is stable; the optimization of the vacuum is significantly affected by water temperature, and the end difference is stable。

2.3 Assist in observing the surfaces of gel balls and other similar objects

Blue rubber ball: 1#Crew; Red rubber ball: 3#Crew;

Observation and comparison using an electron microscope 2 The effect of the rubber balls in the two condensers,1#crew and 3#. The crew's rubber ball there are no obvious differences on the surface, nor any signs of limescale crystallization。

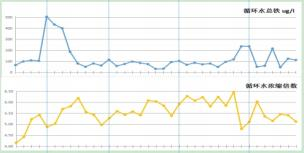

2.4 The inhibition of corrosion in circulating water systems

After the implementation of the technical modification plan for Unit 1 on-site, the concentration of iron ions in the circulating water will be tracked, monitored, and analyzed, as shown in Figure 4。 In the initial phase after the technical upgrade, due to trace amounts of scale in the system(usually mixed scale), The descaling phase leads to a certain amount of iron ions precipitating into the water, resulting in a significant increase in iron ion concentration. After the descaling is completed, the iron ion concentration decreases significantly. As the water quality concentration increases, the iron ion content in the circulating water tends to stabilize。 This indicates that high-frequency electromagnetic fields have a corrosion-inhibiting effect on the circulating water system。

3、Technical principles

3.1 Prevent the formation of new hard water scale inside the heat exchanger

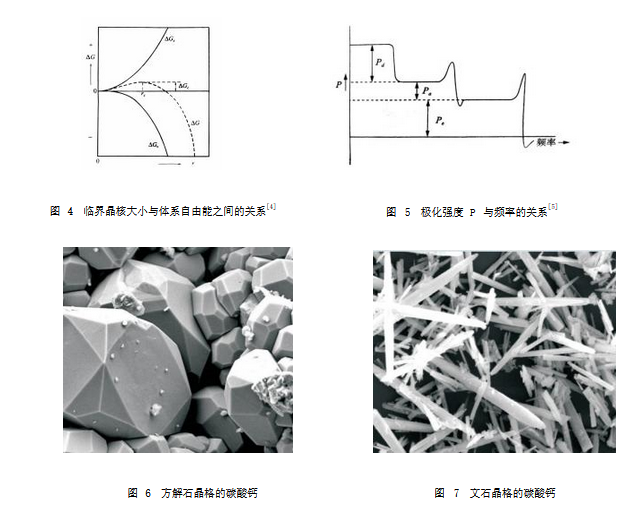

The formation of scale inside heat exchangers is a complex crystallization process. The main substances causing scaling in water are carbonates and sulfates formed by the crystallization of calcium and magnesium. As the temperature increases, their solubility decreases。[2]A portion of calcium and magnesium crystalline substances precipitate and settle down, adhering to the pipes or heat exchange walls, gradually growing into strongly adhering crystalline hard scale, with the main component being a dense calcite lattice (intermediate crystal system, trigonal crystal system, lattice point group 3L23PC), The structural diagram under the electron microscope is shown in Figure 6。

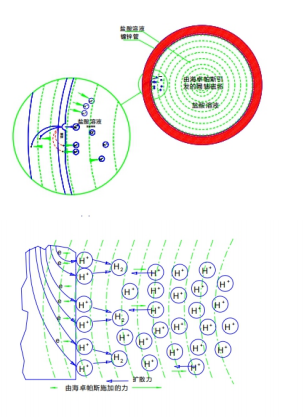

Electromagnetic water treatment equipment is installed at the appropriate location in the pipeline. The high-frequency electromagnetic field generated by the equipment when entering the pipeline is affected by the skin effect of the metal pipeline. Only part of the alternating magnetic field acts on the flowing water, inducing alternating current. The high-frequency polarization current causes the dielectric to repeatedly polarize, promoting the mutual collision of positive and negative ions or particles, and inducing the formation of more“ion aggregates”, which we refer to as crystal nuclei。 When the water temperature inside the heat exchanger rises, the oversaturated calcium carbonate ion clusters gather around the crystal nucleus, forming soft aragonite lattice calcium carbonate (low-level crystal family, orthorhombic crystal system, lattice point group 3L23PC),[3] The structural diagram under the electron microscope is shown in Figure 7。 This crystal structure does not easily adhere to the surfaces of pipes or heat exchangers, thereby preventing the formation of a hard water scale. The crystallized material flows out with the water, being discharged through a side filtration system or drain outlet, or it settles in slower-flowing water pools, ensuring that there is no scale attachment on the inner walls of the pipes and heat exchangers.

3.2 Remove the old scale that has already formed in the cooling water system.

While preventing the growth of calcite calcium carbonate scale, high-frequency electromagnetic fields can also remove existing old scales. The traditional method for removing old scales is chemical acid cleaning, which is difficult to control and can easily cause corrosion to metal containers or result in incomplete cleaning. Choosing physical descaling is the least harmful to the circulation system and the most thorough method, but it requires a longer time。

Tendency to transform into aragonite. As the carbonate and sulfate in the water body precipitate, the hard scale is converted into the soft scale and discharged with the wastewater。

Using induced crystallization granulation to achieve descaling and anti-scaling of cooling water, increasing the concentration ratio of cooling water, thereby helping to achieve zero wastewater discharge for the entire plant。[6]

3.3 Suppress corrosion

The corrosion mechanisms of equipment and pipelines in a circulating water system are quite complex. Generally, chemical corrosion inhibitors are added to form a protective film on the metal surface, or cathodic protection is used to control corrosion. However, under the influence of a high-frequency electromagnetic field, the eddy magnetic field induces an alternating electric field, which spreads throughout the water in the pipeline system. This prevents the formation of cathodic and anodic zones on the surfaces of the pipe walls and equipment walls, respectively, [7] Achieving the effect of corrosion inhibition。

4、Conclution

In the future, the hardware and software of the equipment used in this experiment will be upgraded to the“MIA Mapping Integral Abundance Energy Threshold Operation” and Maintenance Monitoring System. With the enrichment of machine learning and databases, continuous optimization of iterative algorithms, and more stable AI intervention, the operation of the cooling water system will also become safer and more reliable。

References:

[1]Yamei Jin. Research on the Effects of Alternating Magnetic Fields on Food Systems in Open and Closed Circuit States[D].Jiangnan University,2017.

[2]Guofu Lai,Guohua Gao,Yanfei xiao,Zhifeng Xu.Research Progress on the Solubility Phase Diagram of Calcium Sulfate in Chloride-Sulfate Systems[J].Inorganic Salts Industry,2018,50(08):16-21.

[3]Jianguo Wang, Li Song, Junfeng Huang, Yanhong Li.Experimental Study on the Influence of Electromagnetic Field on the Behavior and Morphology of CaCO3 Scaling on Heat Exchange Surfaces[J].Chemical Engineering Journal,2013,64 (10):3708-3713

[4]Crystallization Fourth Edition, J.W.Mullin, ISBN:978-0-7506-4833-2

[5]Electromagnetic Theory/(UK) Written by Maxwell; Gege Translation.—Beijing: Beijing University Press,2010.1(Science Literacy Library ·Scientific Classics Series) ISBN 978--301-16515-7

[6]Chuixin Kong. Experimental Study on the Mechanism of Scale Inhibition in Alternating Electromagnetic Fields[D].Shandong University,2016.

[7]Dandan Zhao, Shunan cao, Chendong, Shenzhen.Research Progress on the Application of Electrolytic Technology in Circulating Cooling Water Treatment[J].Thermal power generation,2018,47(06):1-7.

Cooling system descaling and anti-scaling

Steam boiler scale control

Scale-prevention of hot water boiler

Waste heat boiler scaling

Waste heat recovery equipment scaling

Thermal center scaling and anti-scaling

Reverse osmosis membrane scale removal and anti-fouling

Descaling and Fang of plate heat exchanger

Descaling and fang of steam generator

Air can remove scale and prevent scale from water heaters

Shell and tube heat exchanger scale removal and prevention

Kitchen equipment scale control

Central air conditioning system scale control

Hotel hotel scale control

Chemical plant scale removal and control

Descaling and anti-scaling in mining and metallurgical plants

Hospital scale removal and prevention

Descaling and deterring of iron and steel works

Mining plant scale removal and control

Air compressor scale control

Power plant scale removal and control

Cleaning and preventing scale in paper mill

Scale removal and anti-scaling in electronics factory

Electroplating plant scale control

Cleaning and preventing scale in printing and dyeing plant

Cleaning and preventing scale in food factories

Domestic hot water system to remove and prevent scale

info@como-aqua.com

Company address:Building 9, No. 285 Rongxing Road, Songjiang District, Shanghai