Good news! A certain 300MW project in Henan has been successfully installed and put into operation.

A certain power company in Henan Province is an enterprise primarily engaged in power generation, electricity supply, and the comprehensive utilization of fly ash。

On May 18, Como conducted equipment installation at a self-built power plant in Henan, and the relevant technical personnel from the production department arrived at the installation site early to carry out preliminary on-site inspection work。

The technicians at Como are extremely dedicated, continuously checking the equipment before installation, leaving no room for error. They were also very cautious throughout the installation process, working diligently from the morning of the first day until the evening of the second day。

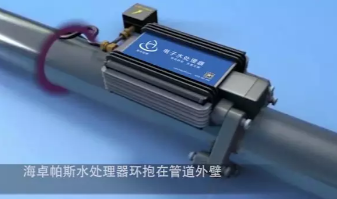

The above image shows the four 1.4-meter devices that have already been installed, which are part of the cooling system for two sets of 150,000-kilowatt units。

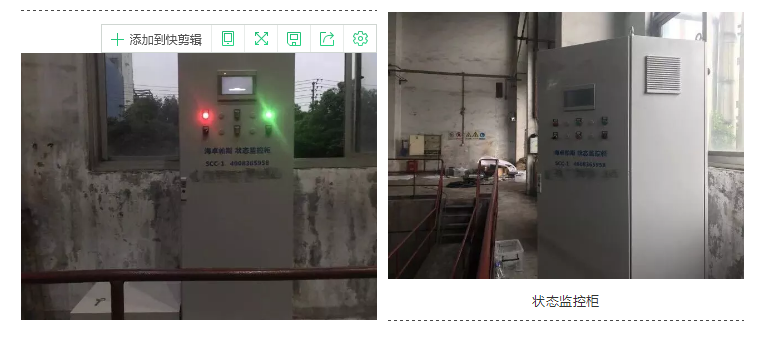

Two status monitoring cabinets have been installed on-site, allowing us to remotely monitor the equipment's status, reducing the workload for personnel and eliminating the need for special maintenance。

Como installation site:

On May 20th, the installation of our equipment is nearing completion, but a few of our team members need to stay here to continue training and handing over the equipment operations to the factory technicians. You've all worked hard; let's give a thumbs up to our technical team at Como。

May 29

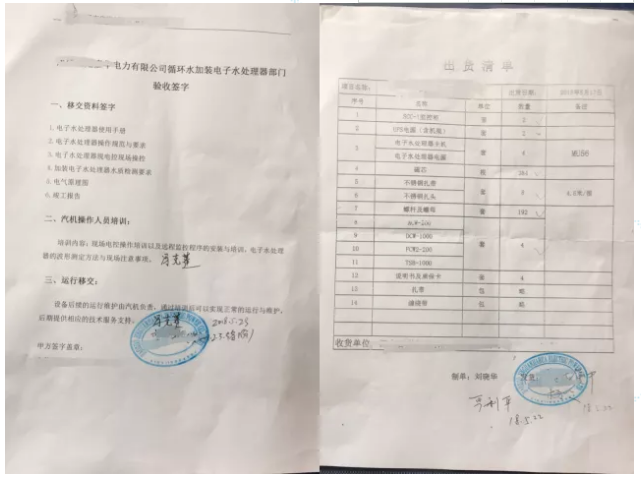

The above is the acceptance form for the Como water treatment system.

Although the on-site unit is operating well, the equipment has been in operation for about 24 hours, and the water quality data shows that it has entered the descaling phase. After three days of operation, all indicators are stable, so the full medication is stopped. After a week of operation, Party A confirms that the system operating parameters are all normal。

On May 29, the partners of Como were on-site for acceptance and handover work。

The Como water treatment system is a single device that can be used in various systems, combining multiple functions such as algae removal and sterilization, descaling and anti-scaling, physical flocculation, and more. It saves 5-30% energy and 75% water。

No need to contact water, no reliance on water flow, no restrictions from piping, no change in chemical composition, no need for shutdowns or production halts, no daily maintenance required, no interference with other electronic devices, minimal power consumption, descaling and anti-scaling, physical flocculation, algae elimination, and sterilization。

Attached: On-site video of Como at the power plant:

Cooling system descaling and anti-scaling

Steam boiler scale control

Scale-prevention of hot water boiler

Waste heat boiler scaling

Waste heat recovery equipment scaling

Thermal center scaling and anti-scaling

Reverse osmosis membrane scale removal and anti-fouling

Descaling and Fang of plate heat exchanger

Descaling and fang of steam generator

Air can remove scale and prevent scale from water heaters

Shell and tube heat exchanger scale removal and prevention

Kitchen equipment scale control

Central air conditioning system scale control

Hotel hotel scale control

Chemical plant scale removal and control

Descaling and anti-scaling in mining and metallurgical plants

Hospital scale removal and prevention

Descaling and deterring of iron and steel works

Mining plant scale removal and control

Air compressor scale control

Power plant scale removal and control

Cleaning and preventing scale in paper mill

Scale removal and anti-scaling in electronics factory

Electroplating plant scale control

Cleaning and preventing scale in printing and dyeing plant

Cleaning and preventing scale in food factories

Domestic hot water system to remove and prevent scale

info@como-aqua.com

Company address:Building 9, No. 285 Rongxing Road, Songjiang District, Shanghai