Industrial cooling circulating water system descaling and anti-scalingSaving water and reducing emissions to help achieve zero discharge

Industrial cooling circulating water system descaling and anti-scalingSaving water and reducing emissions to help achieve zero discharge

Popular search keywords: Electronic scale removerBoiler scale removal and controlCooling water scaling and anti-scaling

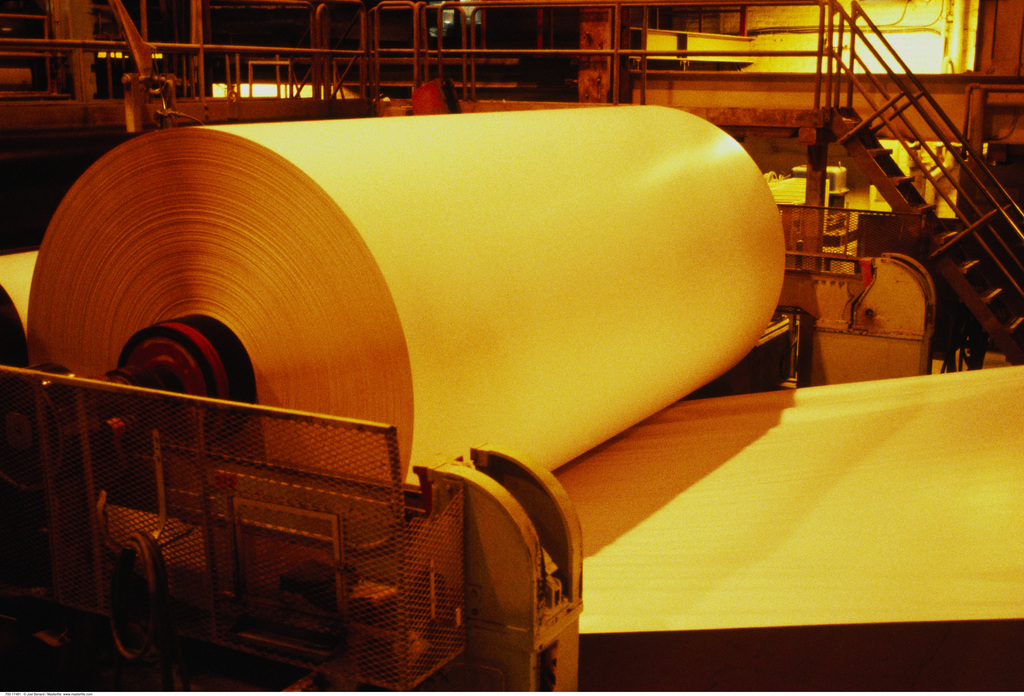

Paper mill descaling and anti-scaling

Paper mill descaling and anti-scaling

Paper mill descaling and anti-scaling The scale removal and prevention in paper mills are divided into two parts: the circulation of ordinary process cooling water, which cools liquids with fewer impurities, such as oil, and the reuse of water containing a large amount of pulp and other materials. The former has a simpler processing method, while the latter is more difficult to handle. Due to the physical flocculation principle of the Como electronic descaling device, it has a flocculation effect on small particles such as pulp, so the effectiveness of descaling and anti-scaling is not only limited to calcium carbonate. The Como electronic descaling device is capable of handling many complex environments, which is unmatched by other products.

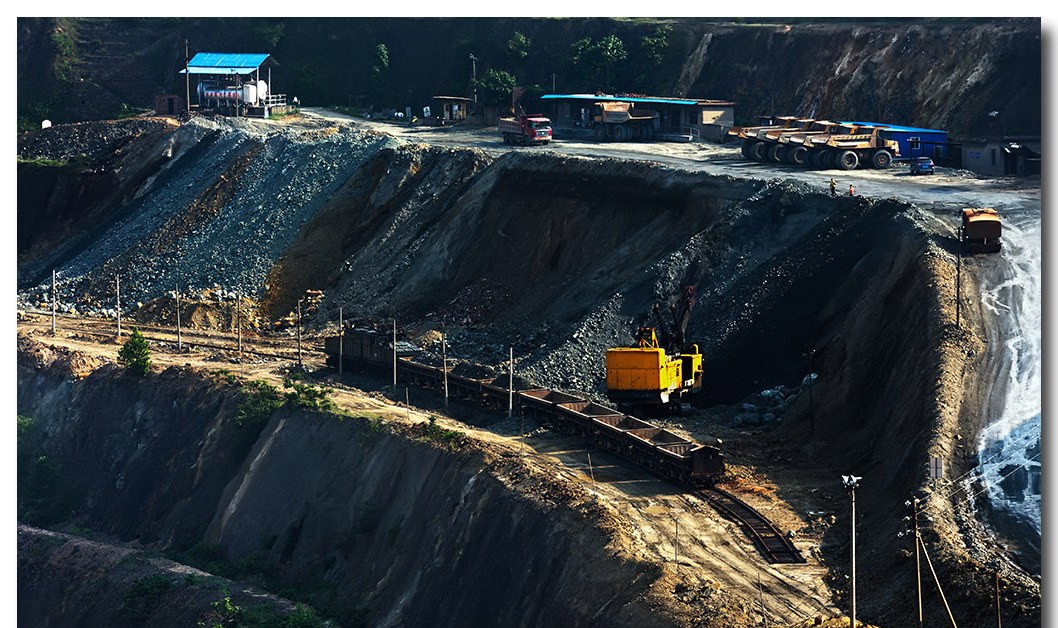

Mining plant descaling and anti-scaling

Mining plant descaling and anti-scaling

Mining plant descaling and anti-scaling The main requirements for scale removal and prevention in mining plants are equipment cooling and waste heat recovery, as well as groundwater recycling and reuse (reverse osmosis membrane). The difficulty lies in the fact that mines are often located in remote areas with complex water quality. Traditional methods of handling are not only difficult to control and costly, but also difficult to achieve long-term results, especially in response to the current advocacy for energy conservation, environmental protection, and emission reduction. The Como electronic descaling device has excellent adaptability and long-term stability, making it the perfect choice for technological improvement!