Industrial cooling circulating water system descaling and anti-scalingSaving water and reducing emissions to help achieve zero discharge

Industrial cooling circulating water system descaling and anti-scalingSaving water and reducing emissions to help achieve zero discharge

Popular search keywords: Electronic scale removerBoiler scale removal and controlCooling water scaling and anti-scaling

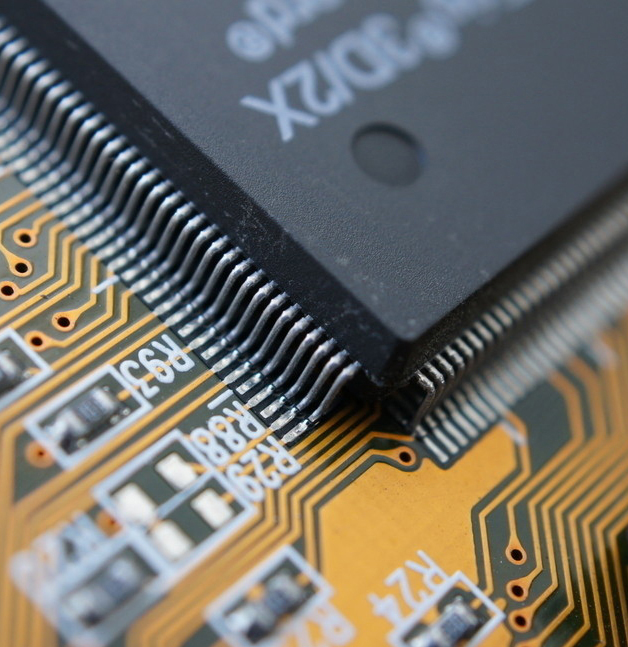

Descaling and anti-scaling for electronic factories

Descaling and anti-scaling for electronic factories

Descaling and anti-scaling for electronic factories The scale treatment in electronic factories mainly focuses on production process cooling and reverse osmosis membrane systems. The Como electronic descaling device not only removes and prevents scale but also has physical flocculation ability. It not only makes the circulating water clearer but also reduces the concentration factor to a certain extent, greatly reducing drainage. The protection of reverse osmosis membranes is a great blessing for electronic factories.

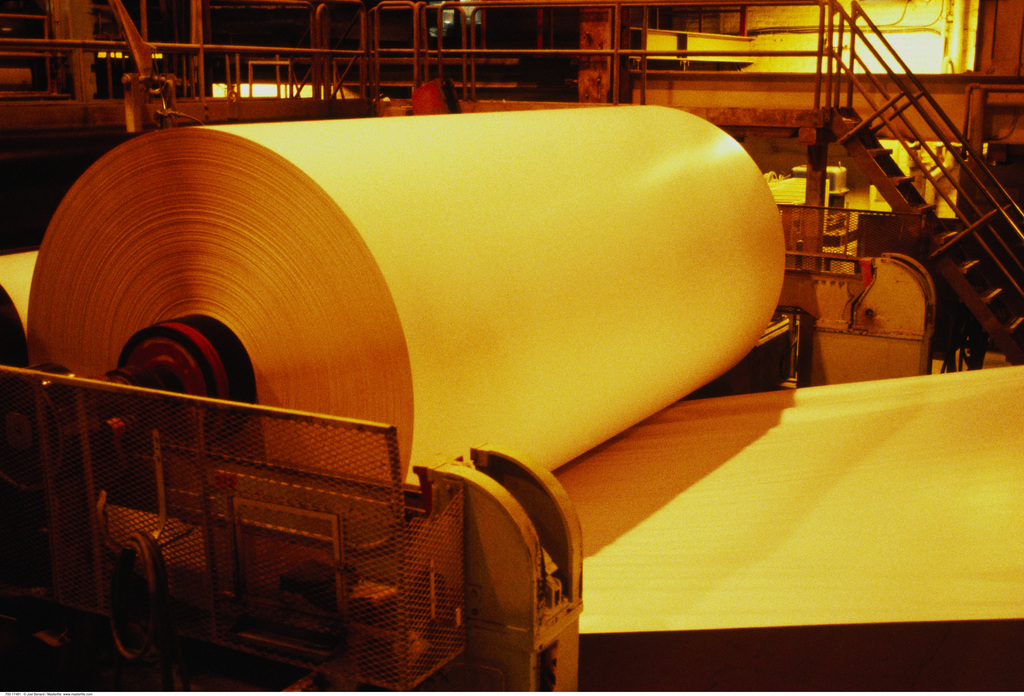

Paper mill descaling and anti-scaling

Paper mill descaling and anti-scaling

Paper mill descaling and anti-scaling The scale removal and prevention in paper mills are divided into two parts: the circulation of ordinary process cooling water, which cools liquids with fewer impurities, such as oil, and the reuse of water containing a large amount of pulp and other materials. The former has a simpler processing method, while the latter is more difficult to handle. Due to the physical flocculation principle of the Como electronic descaling device, it has a flocculation effect on small particles such as pulp, so the effectiveness of descaling and anti-scaling is not only limited to calcium carbonate. The Como electronic descaling device is capable of handling many complex environments, which is unmatched by other products.

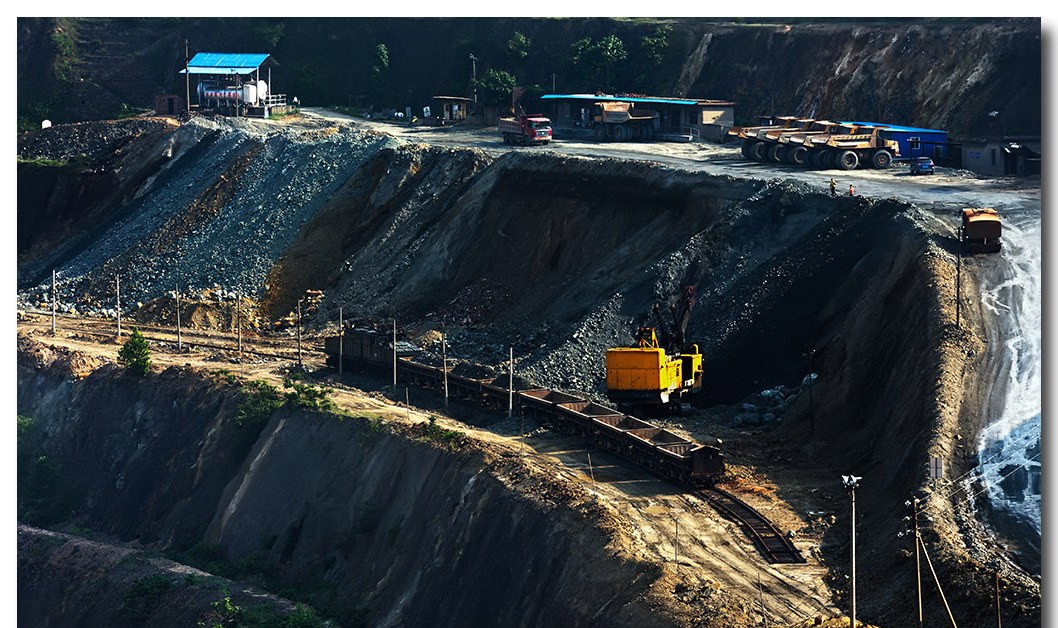

Mining plant descaling and anti-scaling

Mining plant descaling and anti-scaling

Mining plant descaling and anti-scaling The main requirements for scale removal and prevention in mining plants are equipment cooling and waste heat recovery, as well as groundwater recycling and reuse (reverse osmosis membrane). The difficulty lies in the fact that mines are often located in remote areas with complex water quality. Traditional methods of handling are not only difficult to control and costly, but also difficult to achieve long-term results, especially in response to the current advocacy for energy conservation, environmental protection, and emission reduction. The Como electronic descaling device has excellent adaptability and long-term stability, making it the perfect choice for technological improvement!

Metallurgical plant descaling and anti-scaling

Metallurgical plant descaling and anti-scaling

Metallurgical plant descaling and anti-scaling The difficulty of descaling and anti-scaling in metallurgical plants lies in the fact that the cooling system mostly cools down high-temperature components, many production equipment have special structures, and the requirements for safety production are particularly high. In addition, the waste heat recovery system is a good helper for energy reuse in terms of scale removal and prevention. The Como electronic descaling device not only removes and prevents scale but also has physical flocculation ability, which not only makes the circulating water clearer but also reduces the concentration factor to a certain extent, greatly reducing drainage. So, the Como electronic descaling device, which physically removes and prevents scale and does not disassemble pipelines, is the absolute choice for metallurgical enterprises!

Chemical plant descaling and anti-scaling

Chemical plant descaling and anti-scaling

Chemical plant descaling and anti-scaling The descaling and anti-scaling treatment in chemical plants is mainly used to eliminate the efficiency decline caused by scale in cooling circulation systems, refrigeration, and steam boiler systems. The production equipment is mostly jacketed reactors and various heat exchangers. Scale treatment is not only about energy saving but also about removing safety hazards as well as reflecting production quality and efficiency. The Como electronic descaling device ensures safe and efficient production for enterprises once and for all.

Hospital Scale Removal and Prevention

Hospital Scale Removal and Prevention

Hospital Scale Removal and Prevention The descaling and anti-scaling requirements of hospitals at all levels are for steam boilers or hot water boilers, shell and tube or plate heat exchangers, as well as kitchen equipment such as rice steamers. Medium-sized and above hospitals also have central air conditioning systems. Hospitals are health departments that have high requirements for the hygienic operation of equipment. These devices are prone to scaling, which not only makes them vulnerable and increases energy consumption but also hinders hospital hygiene management. The Como electronic descaling device is energy-saving and environmentally friendly, fully meeting the hygiene, environmental protection, and energy-saving requirements of the medical system. It is a good helper for establishing a green hospital.

Hotel & Guesthouse Descaling & Anti-scaling

Hotel & Guesthouse Descaling & Anti-scaling

Hotel & Guesthouse Descaling & Anti-scaling Various types of hotels provide comfortable accommodation environments for guests, generally equipped with steam boilers or hot water boilers, shell and tube or plate heat exchangers, as well as kitchen equipment such as steaming boxes. Large hotels also have central air conditioning systems. These devices will all suffer damage to equipment and systems due to the adhesion of scale, and their energy consumption will increase. The installation of the Como electronic descaling device does not require shutting down the system and will not cause negative interference to hotel operations and customer experience.